However, if the overhead rate is computed annually based on the actual costs and activity for the year, the manufacturing overhead assigned to any particular job would not be known until the end of the year. For example, the cost of Job 2B47 at Yost Precision Machining would not be known until the end of the year, even though the job will be completed and shipped to the customer in March. For these reasons, most companies use predetermined overhead rates rather than actual overhead rates in their cost accounting systems.

What Are Predetermined Overhead Cost Rates?

It is equal to the estimate overhead divided by the estimate production quantity. First, estimate the total amount of overhead costs expected to be incurred during the period (typically a year). This requires analyzing historical data, considering anticipated changes in production volume, and factoring in any known price increases Bookkeeping for Startups for overhead items. However, ABC can also be more complex and costly to implement than using a predetermined overhead rate. The decision of whether to use predetermined overhead rates or ABC often depends on the specific needs and complexity of the organization.

The Accounting Department: Guardians of Cost Allocation

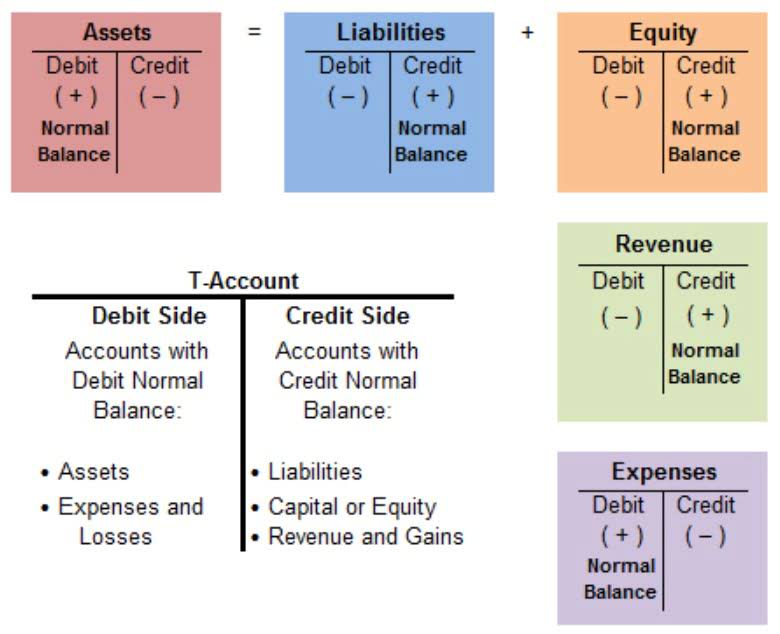

Overhead rates refer to the allocation of indirect costs to the production of goods or services. They represent a percentage or rate that is applied to an appropriate cost driver, such as labor hours or machine hours, to assign overhead costs to products. Figure 8.41 shows the monthly manufacturing actual overhead recorded by Dinosaur Vinyl. As explained previously, the overhead is allocated to the individual jobs at the predetermined overhead rate of $2.50 per direct labor dollar when the jobs are complete.

Unit Converter

Financial analysts leverage overhead data to gain valuable insights into the company’s financial performance and to support strategic decision-making. This option is best if you have some idea of your costs but don’t have exact numbers. Once costs are broken down, small businesses can assess if any categories are excessive.

Using a Single Rate for Different Departments

A predetermined overhead rate is used in a manufacturing company to allocate overhead costs to individual products or services. This information is used for cost accounting purposes, inventory valuation, and pricing decisions. The predetermined overhead rate allocates estimated total overhead for an accounting period across expected activity or production volume.

- As your business grows and becomes more complex, you can refine your methodology.

- Implementing preventive maintenance programs can minimize costly repairs and downtime.

- The predetermined overhead rate is a crucial factor in calculating the overhead costs of a business.

- Examples of manufacturing overhead costs include indirect materials, indirect labor, manufacturing utilities, and manufacturing equipment depreciation.

- Similarly, the predetermined overhead rate allows a business to use consistent costing standards with its products.

- Using this calculation gives the best possible estimation of costs based on relatively comfortable overhead estimations.

- Yes, it’s a good idea to have predetermined overhead rates for each area of your business.

This rate would then charge $4 of overhead to production for every direct labor hour worked. It allows overhead to be assigned to production based on activity (DLHs), providing insight into profitability across products. So petty cash in summary, the overhead rate formula relates your indirect operating costs to production costs.

- It is equal to the estimate overhead divided by the estimate production quantity.

- This foresight is invaluable for competitive bidding, seasonal pricing, or launching new products without risking underpricing.

- The predetermined overhead rate is calculated by dividing the estimated total overhead costs for the period by the estimated total amount of the allocation base (like direct labor hours or machine hours).

- For e-commerce operations, allocation bases might include the number of orders processed, website traffic costs, or even storage space used in a fulfilment centre.

- Direct costs are expenses traced to specific products like raw materials or direct labor.

Properly calculating and what is predetermined overhead rate applying overhead rates is an important accounting process for businesses to absorb indirect costs into their job costing system and product pricing. At the end of the accounting period, you’ll have a difference (called a variance) between your applied overhead (using the predetermined rate) and your actual overhead costs. If you applied more overhead than you actually incurred, that’s an over-applied overhead. Then, at the end of the year, you’d adjust for any overapplied or underapplied overhead based on the actual costs and machine hours for the year. This method helps provide more accurate product costing and financial reporting, but it does require a reasonable and consistent method of estimating costs and activity bases. Finally, as discussed above, some businesses may calculate their predetermined overhead rates based on historical information.

As the name implies, these overhead rates take into account the entire plant and not a particular segment or department. The plantwide overhead rate might not help obtain exact figures, but the estimates are efficient enough for better planning. There are several reasons why businesses need to calculate a predetermined overhead rate. This stage marks the culmination of the cost allocation process, providing a complete view of all expenses tied to the production of a good or service.